CSD - Miscellaneous (TDS, Solid & Water Density, etc.)

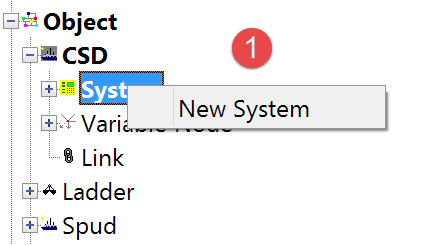

Miscellaneous System Definition

Various observations are definable under the Miscellaneous Systems category. For example: wind speed and direction, water temperature, TDS, water density, solid density.

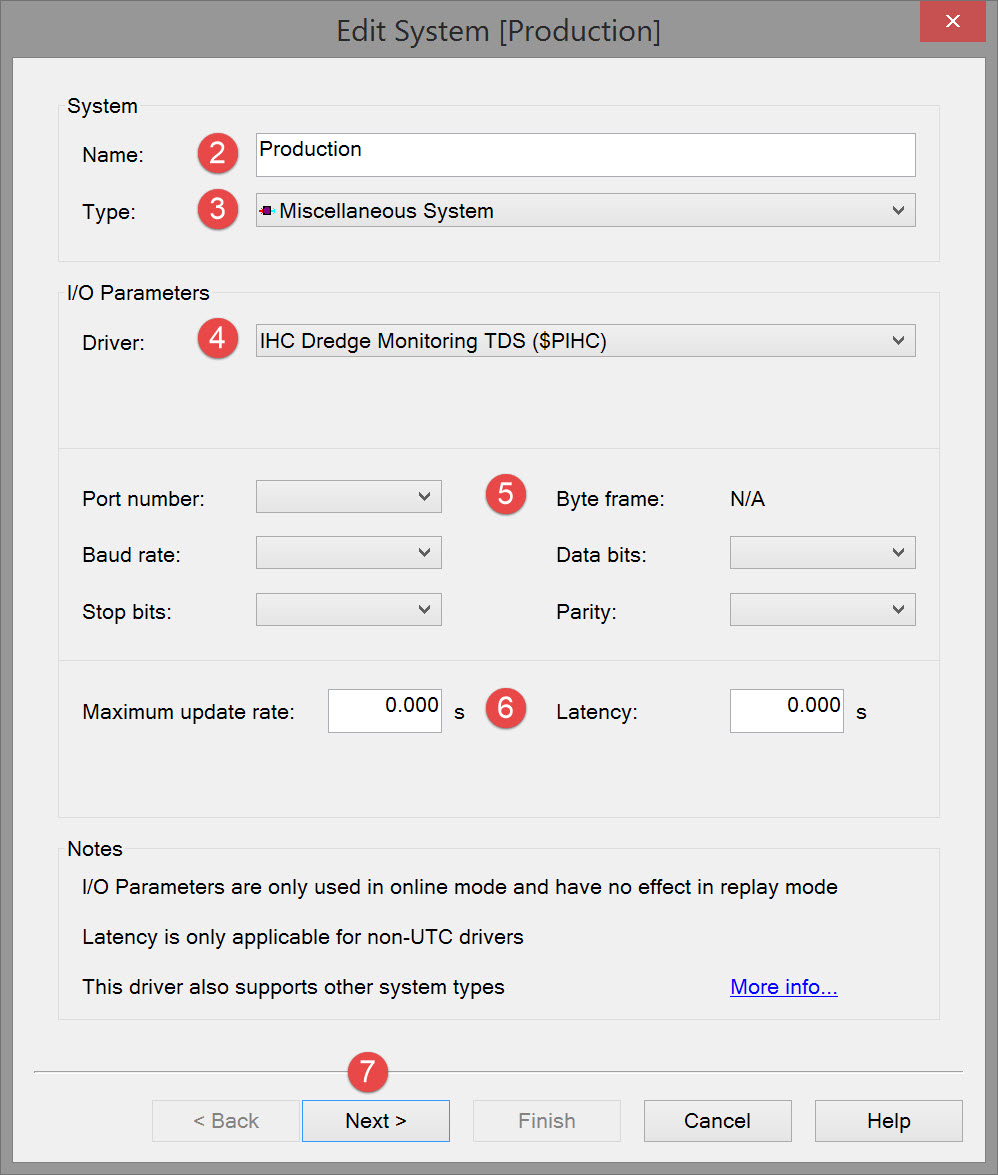

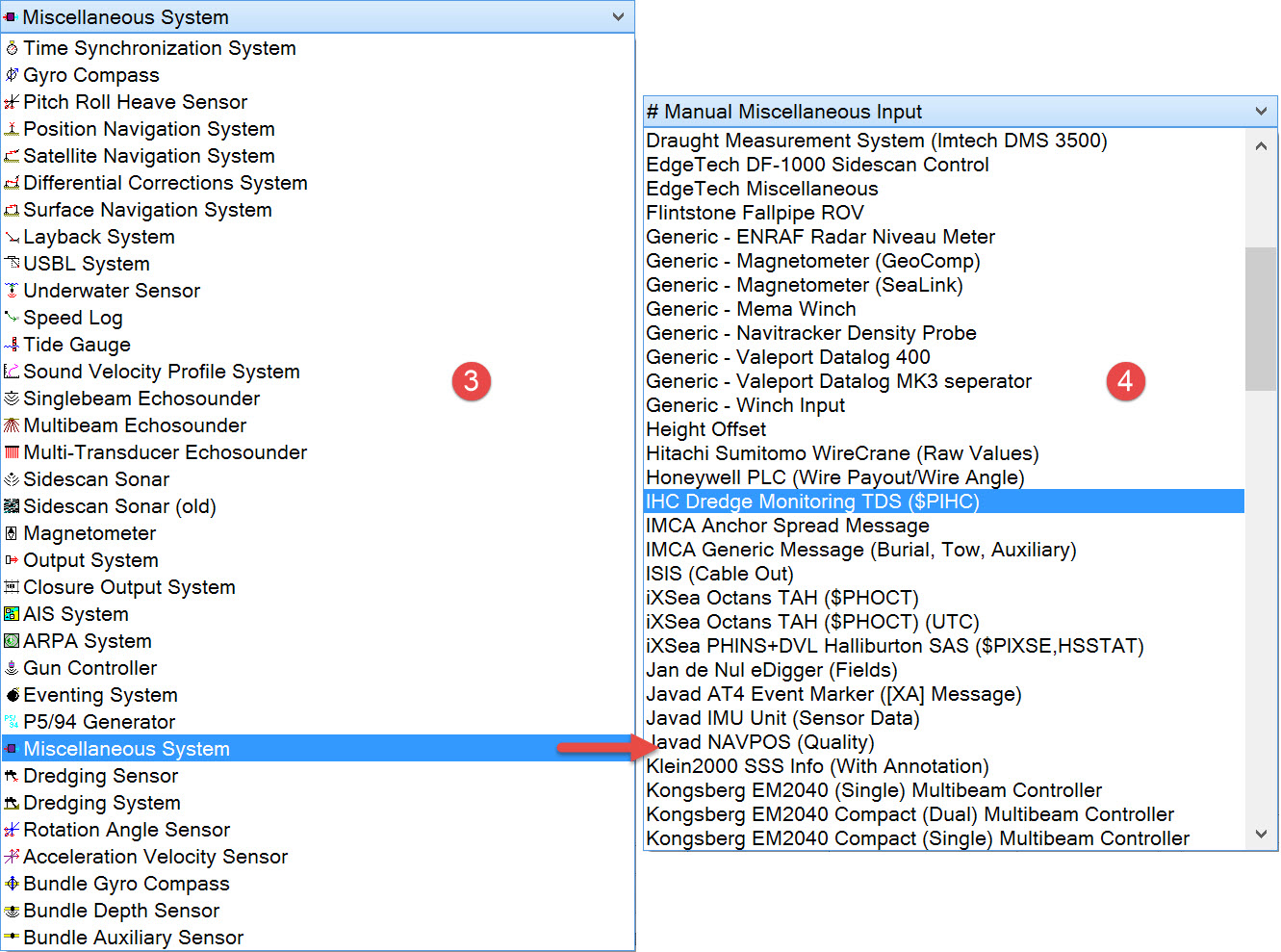

The following dialog opens. It is the first page of a wizard that steps you through the system definition process.

Note that the interfacing can be either serial or network so make sure to select the correct type.

Please refer to A Note on Interfacing Parameters.

Updates | |

|---|---|

| Maximum update rate | Enter a value to determine how often data will be decoded by the interface driver. Some equipment is capable of outputting data at high output rates, but it may not be necessary to use each update. A sensor system may for example output values hundreds of times per second, where five times per second is sufficient. In this case, enter a value of 0.20s. Any data not decoded by the driver is lost and cannot be recovered later. |

| Latency | Latency is the time between the actual measurement made in the sensor system and the time the data message arrives at the port. The time in QINSy will thus be the arrival time corrected with the latency. Modern sensor systems will exhibit no latency, or will have compensated for the latency in the time tag of each data message. |

This is in order that the software can 'marry' the right data value to the observation.

Enter the identifier in the Slot field. Note that the Drivers and Interfacing Manual has identifier listings for many of the Miscellaneous System drivers.

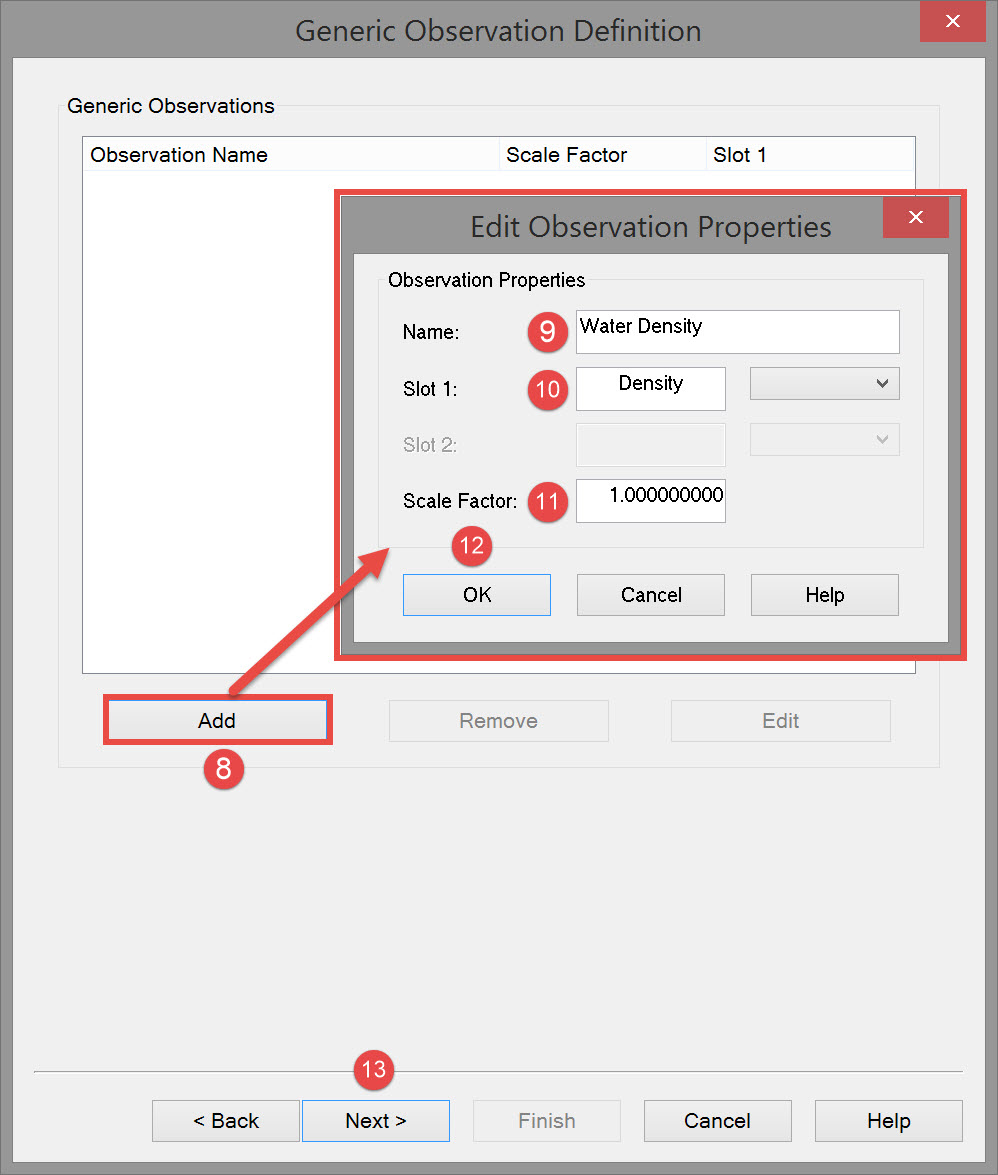

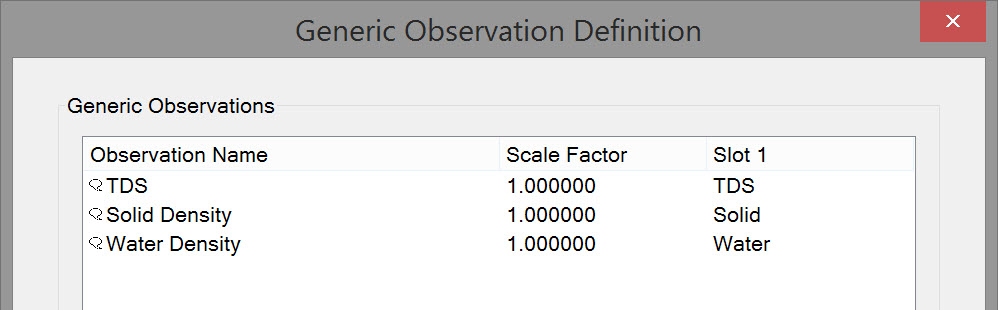

If additional observations must be defined, click on the Add button again and repeat the process. A final definition might look like this:

To change observation names and/or slots use the Edit button to reopen the Edit Observation Properties dialog.

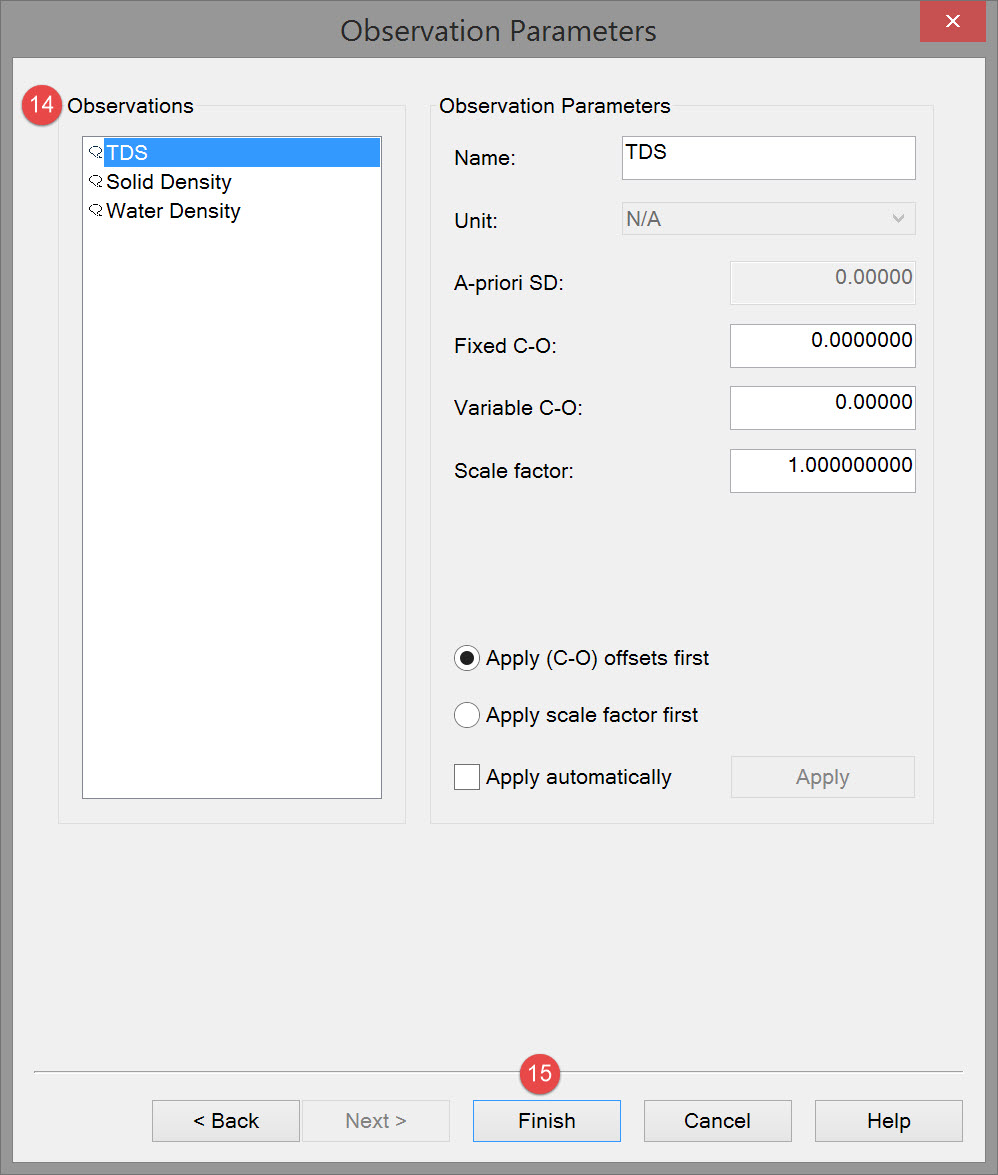

Observation parameters | |

|---|---|

| Name | Enter a descriptive name for the observation. |

| Unit | Select the appropriate observation unit. In some cases there will only be one choice. |

| a-priori SD | Enter the SD for each observation in turn. |

| Fixed C-O | Constant correction to the parameter value. |

| Variable C-O | Variable correction to the parameter value. |

| Scale factor | Use scale factor to convert the raw output to units in the Acquisition Software. For example if local output is in centimeters, then enter scale factor 0.01 here to convert to meters. |

| Apply C-Os offsets first | C-Os are added or subtracted before a scale factor is applied. |

| Apply Scale factor first | Scale factor is applied before C-Os are applied. |

| Apply automatically | The order in which corrections are applied is done in the software. |

Return to top of page.

Return to: Cutter Suction Dredger (CSD) - System Definitions