Network - IHC Dredging Positions (ASCII) - 15

Description

This is a driver to exchange information with the IHC DigiSys system.

The main function of the IHC DigiSys system is to present dredging information on board a cutter suction dredger.

It is capable of sending and receiving ASCII-based messages.

The message that is sent by the driver contains the following types of information:

Tide information: used tide value and status

3D position of the pontoon in projection grid coordinates including position & height status

Work spud chainage and offset to the active center line

Projection grid convergence

Some spare fields

The message that is received by the driver contains the following types of information:

Draft of the pontoon

Spud carrier position

Pitch & roll of the pontoon

Tide information: used tide value and status

Heading of the pontoon

Density & velocity of mixture

Cutter head identifier

Ladder angle

Roll & pitch of the the work spud

Relative & Absolute position of center of cutter

Relative & Absolute position of cut point

Relative & Absolute position of calibration point

Relative & Absolute position of work spud tip

Relative & Absolute position of auxiliary spud tip

Absolute position of starboard anchor

Absolute position of port anchor

10 user configurable observations

Driver Information

Driver | Network - IHC Dredging (ASCII) | Interface Type | Network UDP | Driver Class Type | Terminated |

|---|---|---|---|---|---|

No | Input / Output | Input and Output | Executable | DrvOutIhcUdp.exe DIGISYS_ASCII | |

Related Systems |

| ||||

Related Pages | |||||

Coding Notes

Encoding Notes

Tide Information

The tide value only contains a value if Qinsy is actively using a tide observation for the height observation. If this is the case the tide status will be set to 'valid'.

Position Information

The position information as outputted is using the survey projection and vertical chart datum as its horizontal & vertical references.

Work Spud Information

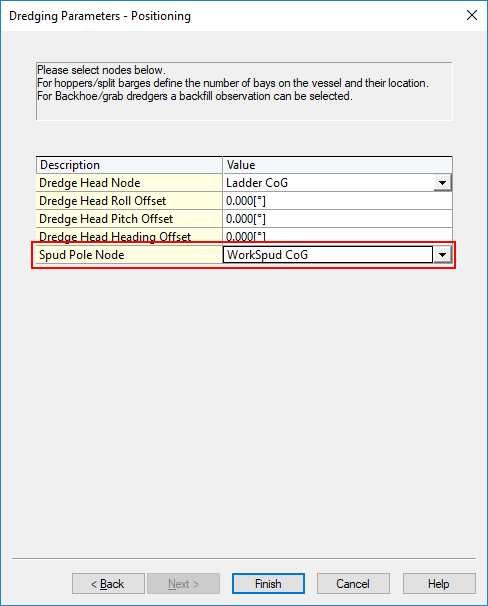

The work spud information is computed using the position of the spud node as selected in the 'Dredging Parameters - Positioning' dialog in the Database Setup Program.

Project Grid Convergence

The convergence field uses the following convention: Convergence = True bearing - Grid bearing.

Spare Fields

The spare fields are currently not used and therefore remain 0.0.

System Interfacing

The driver is normally connected to the DigiSys system using a network connection and uses the UDP protocol as means of communication. The driver is redundancy enabled.

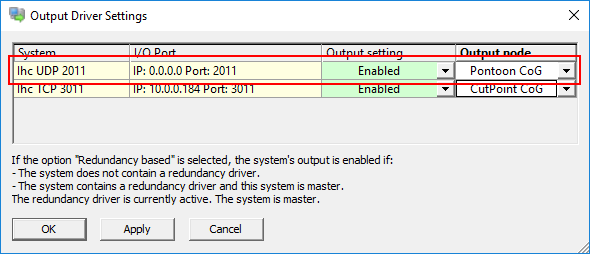

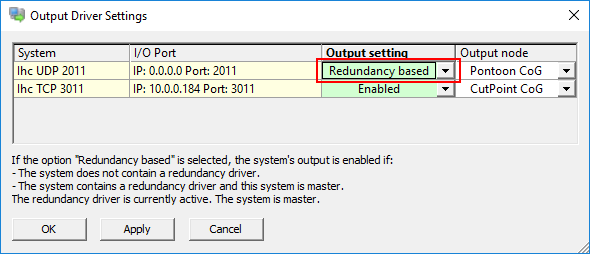

This means that the driver will adhere to the settings as found in the 'Controller - Output Driver Settings' dialog as shown below:

System Configuration

The DigiSys system should be configured to use the same UDP port as set in the Qinsy template database.

Qinsy Configuration

Database setup

The driver is able to extract information for the following system types from the input message:

Position System

The following absolute positions are available from the input message:

Center cutter

Cut point

Calibration point

Work spud tip

Auxiliary spud tip

Starboard anchor

Port anchor

In order to decode any of these absolute positions:

Add a Position Navigation System to your template and select the driver "Network - IHC Dredging (DigiSys)".

The port number should be the same as in the DigiSys system. By default this will be port 2011.

The IP address should be 0.0.0.0 unless we want to send to a specific IP address.

The maximum update should be set to the required output message rate. Normally this will be 0.200 s (= 5 Hz)

Select for Horizontal and Vertical datum the survey datum.

Select the appropriate value for the 'Receiver number' field.

Available are:

Receiver number | Position |

|---|---|

CentCutter | Center cutter |

CutPoint | Cut point |

CalPoint | Calibration point |

WorkSpudTD | Work spud tip |

AuxSpudTD | Auxiliary spud tip |

AnchorSB | Starboard anchor |

AnchorPS | Port anchor |

Heading System

The driver is capable of decoding the pontoon heading from the input message.

In order to decode the pontoon heading from the input message:

Add a Gyro and Compass system to your template and select the driver "Network - IHC Dredging (DigiSys)"

The port number should be the same as in the DigiSys system. By default this will be port 2011.

The IP address should be 0.0.0.0 unless we want to send to a specific IP address.

The maximum update should be set to the required output message rate. Normally this will be 0.200 s (= 5 Hz).

Set the appropriate value for the 'Slot number 1' field.

Available are:

Slot number 1 | Heading for object |

|---|---|

HdgPontoon | Pontoon |

HdgLadder | Ladder |

HdgSpud1 | Main Spud |

HdgSpud2 | Auxilary Spud |

HdgStbd | Starboard Anchor |

HdgPort | Port Anchor |

HdgCutter | Cut Point |

HdgCalib | Calibration |

HdgCenter | Cutter Center |

HdgSafety | Safety Heading |

Hdg01 - Hdg10 | Future Expansion |

Remark: All possible slot numbers result in the same value for the heading but they may be used to create headings for all mentioned objects.

USBL system

The driver is capable of decoding a number of relative positions from the input message:

Center cutter

Cut point

Calibration point

Work spud tip

Auxiliary spud tip

All relative positions use the APP point as a reference and are present in Qinsy as USBL observations.

In order to decode any of these relative positions:

Add a USBL System to your template and select the driver "Network - IHC Dredging (DigiSys)".

The port number should be the same as in the DigiSys system. By default this will be port 2011.

The IP address should be 0.0.0.0 unless we want to send to a specific IP address.

The maximum update should be set to the required output message rate. Normally this will be 0.200 s (= 5 Hz)

On the first 'USBL system Parameters' page select the APP node as Reference Node.

Set the following fields in the 'Corrections Already Applied to Data' section:

Set the 'Roll' field to 'None' to indicate that no roll correction was applied in the DigiSys system.

Set the 'Pitch' field to 'None' to indicate that no pitch correction was applied in the DigiSys system.

Set the 'Heading' field to 'None' to indicate that no heading correction was applied in the DigiSys system.

On the 'USBL Targets' page add the appropriate nodes as USBL targets and set the correct 'Slot 1' field.

Available are:

Slot 1 | Position |

|---|---|

CentCutter | Center Cutter |

CutPoint | Cut point |

CalPoint | Calibration point |

WorkSpudTD | Work spud tip |

AuxSpudTD | Auxiliary spud tip |

Pitch Roll Heave Sensor

The system is capable of decoding two Pitch Roll Heave Sensors from the input message:

Pontoon (roll & pitch only)

Work spud (roll & pitch only)

In order to decode any of these Pitch Roll Heave Sensors:

Add a Pitch Roll Heave Sensor to your template and select the driver "Network - IHC Dredging (DigiSys)".

The port number should be the same as in the DigiSys system. By default this will be port 2011.

The IP address should be 0.0.0.0 unless we want to send to a specific IP address.

The maximum update should be set to the required output message rate. Normally this will be 0.200 s (= 5 Hz).

Select the appropriate value for the 'Slot' field. Available are:

Slot | Pitch Roll Heave |

|---|---|

VruPontoon | Pontoon Roll & Pitch |

VruSpud | Work spud Roll & Pitch |

Tide Gauge

The driver is capable of decoding the DigiSys used tide measurement from the input message.

In order to decode the tide measurement from the input message:

Add a Tide Gauge system to your template and select the driver "Network - IHC Dredging (DigiSys)"

The port number should be the same as in the DigiSys system. By default this will be port 2011.

The IP address should be 0.0.0.0 unless we want to send to a specific IP address.

The maximum update should be set to the required output message rate. Normally this will be 0.200 s (= 5 Hz).

On the next page add a Tide observation and connect to the correct node.

The 'Slot 1' field on the this page should be set to 'Tide'

Miscellaneous System

The driver is capable of decoding a number of miscellaneous observations from the input message:

Spud carriage position

Cutter head identifier

10 User configurable observations

In order to decode any of these miscellaneous observations:

Add a Miscellaneous System to your template and select the driver "Network - IHC Dredging (DigiSys)".

The port number should be the same as in the DigiSys system. By default this will be port 2011.

The IP address should be 0.0.0.0 unless we want to send to a specific IP address.

The maximum update should be set to the required output message rate. Normally this will be 0.200 s (= 5 Hz).

On the next page add a Generic observation and set the appropriate observation properties.

Select the appropriate value for the 'Slot 1' field.

Available are:

Slot 1 | Observation |

|---|---|

CutterHead | Cutter head identifier |

Spud | Spud carrier position |

ConfOut01 | User configurable observation 1 |

ConfOut02 | User configurable observation 2 |

ConfOut03 | User configurable observation 3 |

ConfOut04 | User configurable observation 4 |

ConfOut05 | User configurable observation 5 |

ConfOut06 | User configurable observation 6 |

ConfOut07 | User configurable observation 7 |

ConfOut08 | User configurable observation 8 |

ConfOut09 | User configurable observation 9 |

ConfOut10 | User configurable observation 10 |

Underwater Sensor

The driver is capable of decoding the pontoon draft from the input message.

In order to decode the pontoon draft from the input message:

Add an Underwater Sensor to your template and select the driver "Network - IHC Dredging (DigiSys)".

The port number should be the same as in the DigiSys system. By default this will be port 2011.

The IP address should be 0.0.0.0 unless we want to send to a specific IP address.

The maximum update should be set to the required output message rate. Normally this will be 0.200 s (= 5 Hz).

The 'Slot number 1' field on the next page should be set to 'Draft'.

Dredge Sensor

The driver is capable of decoding a number of dredge observations from the input message:

Mixture density

Mixture velocity

In order to decode any of these dredge observations:

Add a Dredge Sensor to your template and select the driver "Network - IHC Dredging (DigiSys)".

The port number should be the same as in the DigiSys system. By default this will be port 2011.

The IP address should be 0.0.0.0 unless we want to send to a specific IP address.

The maximum update should be set to the required output message rate. Normally this will be 0.200 s (= 5 Hz).

On the next page add an observation and set the appropriate observation properties.

Select the appropriate value for the 'Slot 1' field.

Available are:

Slot 1 | Observation |

|---|---|

Velocity | Mixture velocity |

Density | Mixture density |

Rotation Angle Sensor

The driver is capable of decoding the ladder angle from the input message.

In order to decode the ladder angle from the input message:

Add a Rotation Angle Sensor to your template and select the driver "Network - IHC Dredging (DigiSys)"

The port number should be the same as in the DigiSys system. By default this will be port 2011.

The IP address should be 0.0.0.0 unless we want to send to a specific IP address.

The maximum update should be set to the required output message rate. Normally this will be 0.200 s (= 5 Hz).

On the next page add a Rotation-X observation and set the appropriate observation properties.

The 'Slot number 1' field on the next page should be set to 'Ladder'.

Output System

The driver is capable of sending a message containing the information required by the DigiSys system.

In order to send the output message to DigiSys:

Add an Output System to your template and select the driver "Network - IHC Dredging Positions (DigiSys)"

The port number should be the same as in the DigiSys system. By default this will be port 2011.

The IP address should be 0.0.0.0 unless we want to send to a specific IP address.

The maximum update should be set to the required output message rate. Normally this will be 0.200 s (= 5 Hz).

In case multiple Qinsy systems are combined in a redundant setup set the 'Data output' field to 'Redundancy based' in order to enable the redundancy feature.

Qinsy Online

Once the template has been taken online the driver does not show any UI.

The I/O may be checked by monitoring the decoded information in an Observation Physics or Generic display.

The position of the output node as selected in the Controller is used for the APP easting, northing & height fields as found in the output message: