CSD - Dredging System

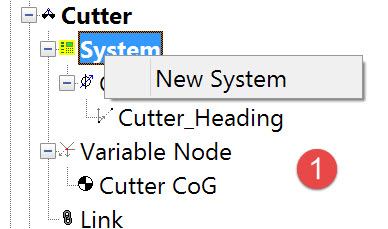

Dredging System

Define the Dredging Sensor System before defining this system.

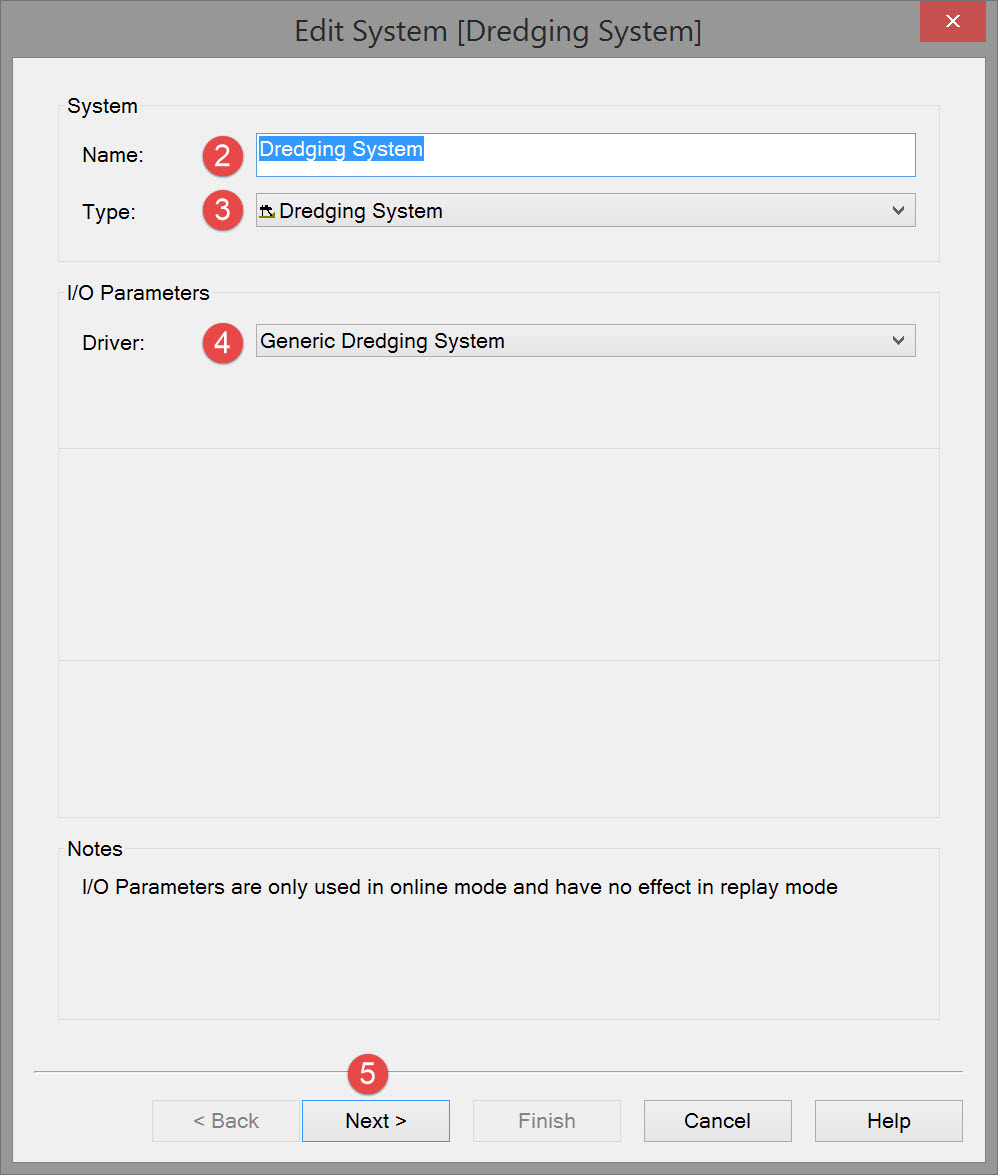

Use the Generic Dredging System to select the type of dredger, activate production calculations, determine origin of the status i.e. from the Eventing driver or the onboard dredging computer.

Prior to defining a dredging system the observations that support the dredging system should be defined (usually part of a dredging sensor system type). For example the dredging status (e.g. dumping/dredging/sailing loaded), current measurement, open/close bay door observation etc. Note that this is optional, all the values can also be entered/overruled online.

This driver listens mainly to other drivers that do the actual interfacing. It generates Dredge Observations (triggers) that drive the dredging process; for example when either an update interval is reached (suction input/output) or when it detects an event from the Eventing system.

The following dialog opens. It is the first page of a wizard that steps you through the system definition process.

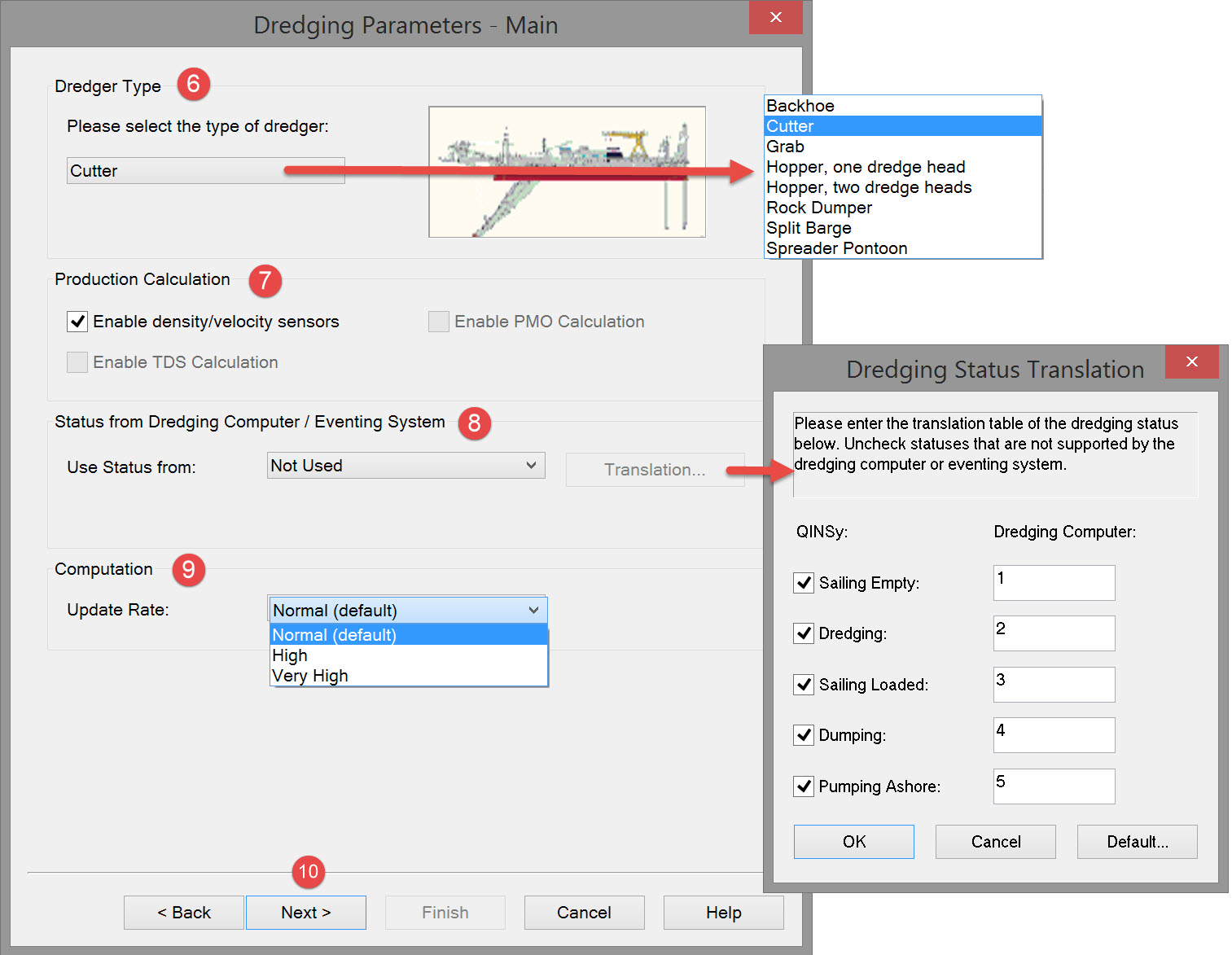

A cutter type dredger doesn't have a hopper and therefore the production can only be calculated if mixture density and mixture speed is known. If the diameter of the pipe is also defined then the production in tons/sec can be calculated. Check this box in order to use the information from these sensors in production calculations.

Select if the status from the dredge computer is to be used or not. If it is set to “Status” QINSy will use the status observation in order to update the grid. For instance if the cutter head enters the seabed and the status isn’t set to dredging the grid will not be updated.

If Status is used, select “Translation” in order to set the correct status observations for each status. So if 'dredging' has a status of '1' and 'not dredging' a status of '0', enter '1' in the Dredging row.

While primarily aimed at other dredging methods, the Dredging status can be used for cutters.

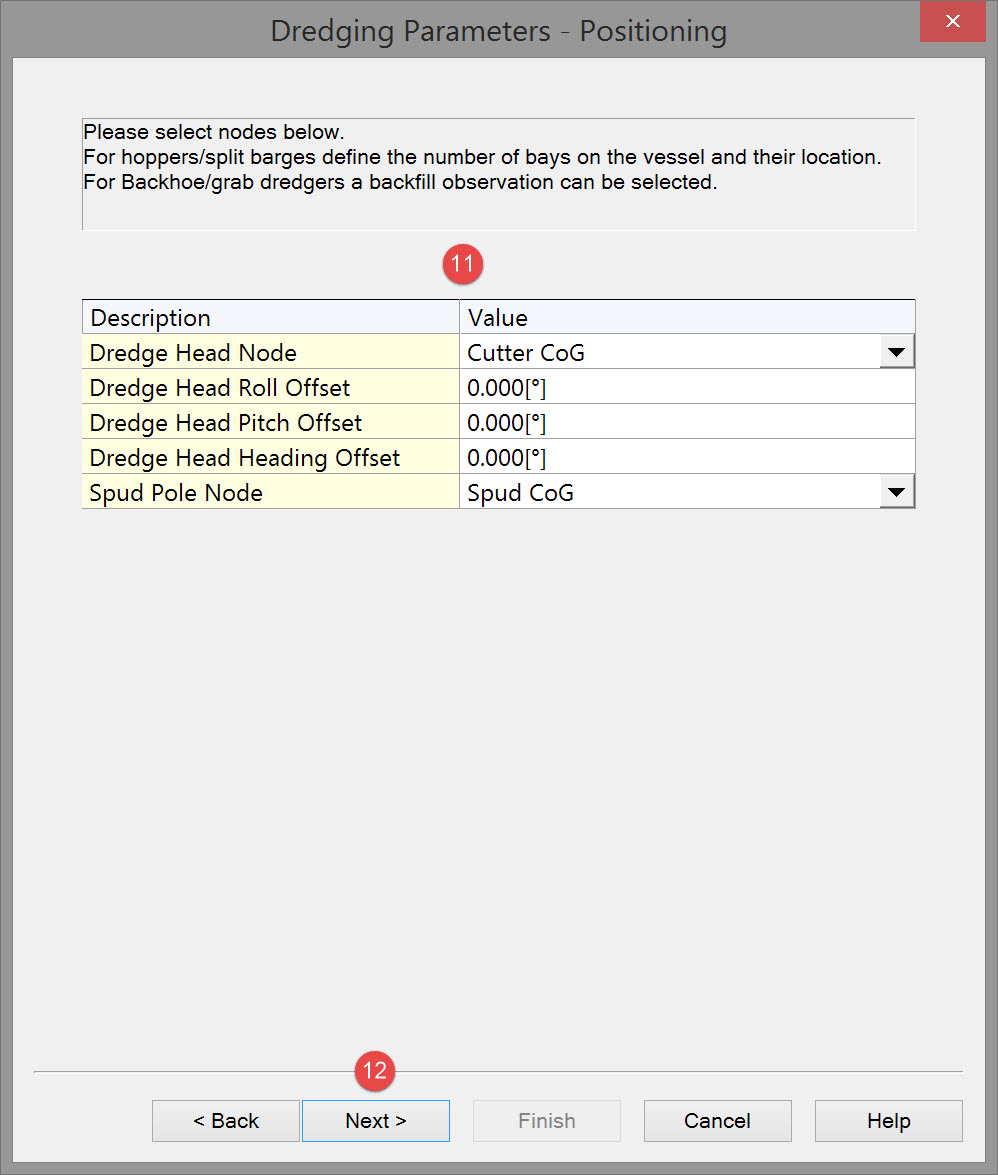

| Description | Value |

|---|---|

| Dredge Head Node | Select the “Dredge Head Node” from the pull down menu. This is the node where the dredge head is attached to the ladder. |

| Dredge Head Roll Offset | The roll offset should be set to 0 degrees. |

| Dredge Head Pitch Offset | For a CSD the pitch offset must be set to 90 degrees. |

| Dredge Head Heading Offset | The heading offset should be set to 0 degrees. |

| Spud Pole Node | Select the node from the pull down menu. Create the node if it is not yet available. |

| Description | Value |

|---|---|

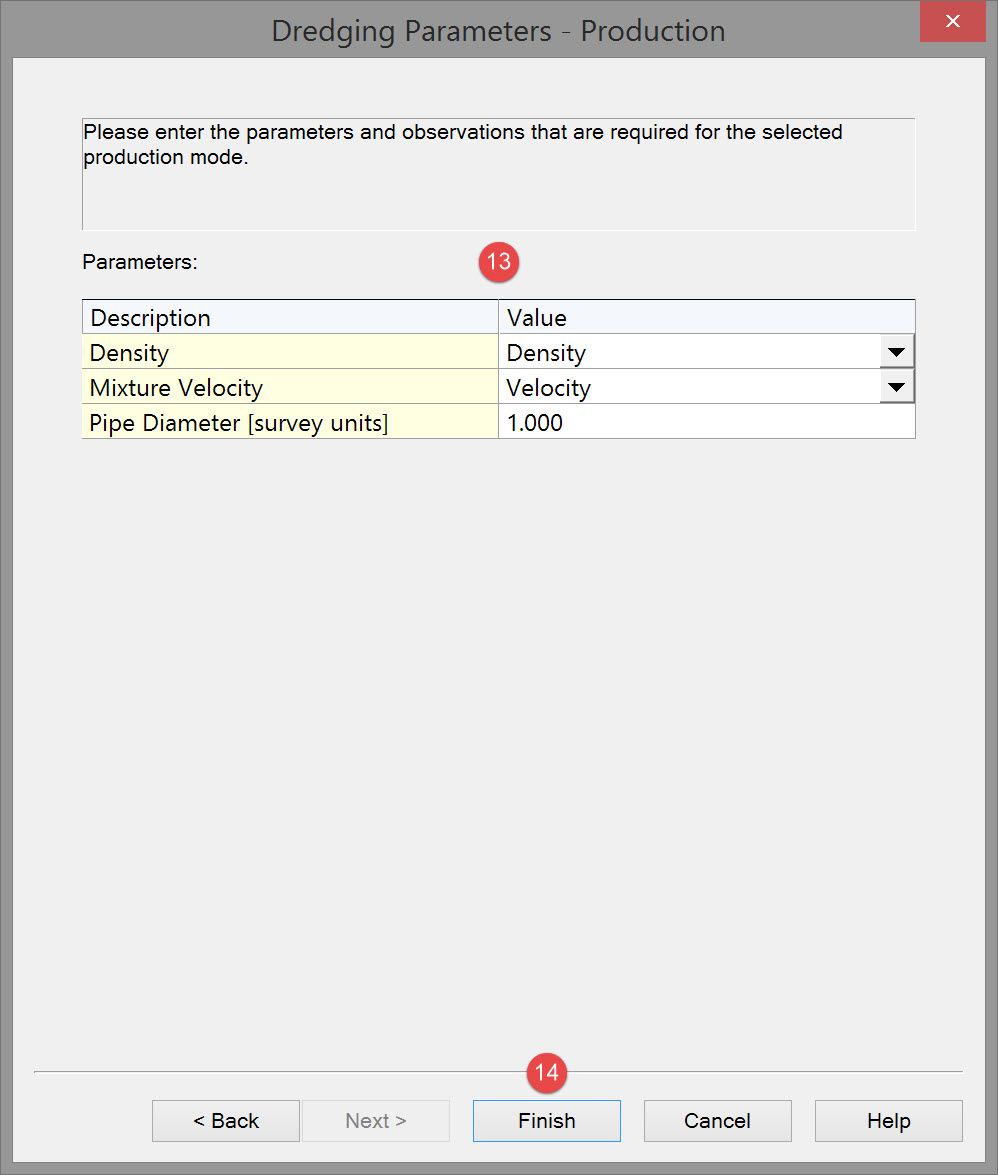

| Density | Select the observation for Density. This observation must be defined in a Dredging Sensor System before it will appear in the list here. |

| Mixture Velocity | Select the observation for Mixture Velocity. This observation must be defined in a Dredging Sensor System before it will appear in the list here. |

| Pipe Diameter (survey units) | Enter the pipe diameter using the units defined for the project. |

These values will be used for the production calculation.

Return to top of page.

Return to: Cutter Suction Dredger (CSD) - System Definitions